Product Description

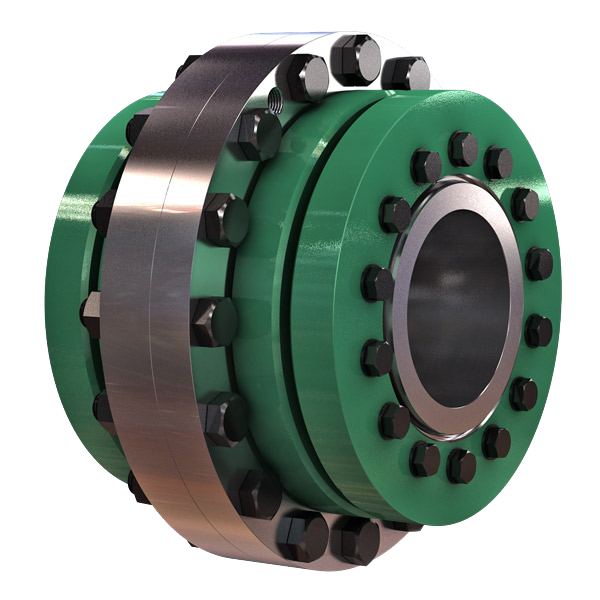

Large curved tooth Drum Type Coupling (GIICL)

Descriprion

GIICL type – the sealing end for the entire body, small spacing between the teeth, the relative allowable radial displacement, compact structure, small moment of inertia, can be connected with the Y, J1 type shaft.

Features

1. Small radial dimension and large bearing capacity are commonly used in shafting transmission under low speed and heavy load conditions.

2. Under the same outer diameter of the inner gear sleeve and the maximum outer diameter of the coupling, the load-carrying capacity of the drum-shaped gear coupling is 15-20% higher than that of the straight-tooth coupling on average.

3. It can compensate for the relative offset of 2 axes at a certain angle and work long distances with the middle axle.

4. It is suitable for connecting horizontal 2 coaxial axes and driving shafting with a certain angle displacement.

A Type (Applicable to GIICL1-GIICL13) B Type (Applicable to GIICL14-GIICL25)

Dimensions

| Model | Tn N.m |

[n] r/min |

D | H | A | C | kg.m² |

mL |

Kg |

||

| Y,J1 | |||||||||||

| d1,d2 | L | ||||||||||

| GIICL1 | 4/8822 0571 1.75 | 33000 | 15015 | ||||||||

| GIICL25 | 4500000 | 460 | 670-1040 | 900-1000 | 1644 | 19.0 | 325 | 50 | 5174.25-7198.25 | 43000 | 24080 |

Our factory

Packing & Delivery

FAQ:

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks in PDF or AI format.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 5: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 6: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Factors to Consider When Choosing a Flange Coupling for a Specific System

When selecting a flange coupling for a specific system, several factors need to be taken into consideration to ensure optimal performance and reliability. Here are the key factors to consider:

- 1. Load and Torque Requirements: Determine the maximum load and torque that the flange coupling will experience in the application. This includes both static and dynamic loads. Select a flange coupling that can handle these loads without exceeding its rated capacity.

- 2. Shaft Diameter: Measure the diameter of the shafts that will be connected by the flange coupling. Ensure that the coupling’s bore size matches the shaft diameter to provide a proper fit and secure connection.

- 3. Misalignment Tolerance: Consider the amount of misalignment that the system may experience during operation. Flange couplings are available in different designs, and some can accommodate higher levels of misalignment than others. Choose a coupling that can handle the expected misalignment to prevent premature wear and stress on the system.

- 4. Operating Speed: Determine the rotational speed of the connected equipment. High-speed applications may require precision balancing and careful selection of materials to prevent issues like resonance and excessive vibration.

- 5. Environmental Conditions: Consider the environmental factors the flange coupling will be exposed to, such as temperature, humidity, dust, and chemicals. Choose a material and coating that can withstand the specific environmental conditions to prevent corrosion and degradation.

- 6. Space Limitations: Evaluate the available space for installing the flange coupling. Some applications may have limited space for coupling installation, requiring compact designs or custom solutions.

- 7. Serviceability: Assess the ease of installation and maintenance of the flange coupling. A coupling that is easy to install and service can reduce downtime and maintenance costs.

- 8. Compatibility: Ensure that the flange coupling is compatible with the equipment and shafts in the system. Consider factors such as keyways, set screws, and other connection methods.

- 9. Material Selection: Choose the appropriate material for the flange coupling based on factors like load, temperature, and corrosion resistance. Common materials include steel, stainless steel, aluminum, and various alloys.

- 10. Cost: Compare the cost of different flange coupling options, considering both the initial investment and long-term maintenance expenses. Balance the cost with the desired performance and reliability.

It is essential to consult with coupling manufacturers or industry experts to ensure the flange coupling’s suitability for the specific application. Properly selecting and installing the right flange coupling can contribute to the efficiency, reliability, and longevity of the connected machinery and system.

Can Flange Couplings Be Used in Hydraulic and Pneumatic Systems?

Yes, flange couplings can be used in both hydraulic and pneumatic systems to connect rotating components, such as pumps, motors, and cylinders, to transmit torque and motion. The key considerations when using flange couplings in hydraulic and pneumatic systems include the choice of material, sealing, and proper design to accommodate the specific requirements of these systems.

1. Material Selection: In hydraulic and pneumatic systems, the choice of material for the flange coupling is crucial due to the potential exposure to various fluids and environmental conditions. Common materials used for flange couplings in these systems include steel, stainless steel, and aluminum, which offer good strength, corrosion resistance, and durability.

2. Sealing: Hydraulic and pneumatic systems rely on the containment of fluids or gases under pressure. Therefore, it’s essential to ensure proper sealing in flange couplings to prevent any leakage that could lead to system inefficiencies or safety hazards. Proper sealing can be achieved using O-rings, gaskets, or other sealing elements integrated into the flange coupling design.

3. Design Considerations: The design of flange couplings for hydraulic and pneumatic systems should take into account the high pressures and forces involved in these applications. The flange coupling design should be robust enough to withstand the operating pressures and torque loads while maintaining proper alignment and ensuring smooth transmission of power.

4. Precision Machining: Tight tolerances and precision machining are critical for flange couplings used in hydraulic and pneumatic systems. This ensures that the coupling components fit together accurately, preventing any air or fluid leakage and minimizing wear and tear.

5. Customization: In some cases, hydraulic and pneumatic systems may have specific requirements that call for customized flange coupling designs. These customizations may include special materials, size, or sealing features to match the unique demands of the system.

Overall, flange couplings offer a reliable and efficient means of connecting rotating components in hydraulic and pneumatic systems. Proper selection, design, and maintenance of flange couplings contribute to the overall performance and longevity of these systems, ensuring smooth operation and minimal downtime.

What are the Maintenance Requirements for Flange Couplings?

Flange couplings require regular maintenance to ensure optimal performance and longevity. Proper maintenance can help prevent unexpected failures and downtime in the machinery or equipment. Here are the key maintenance requirements for flange couplings:

1. Inspection: Regularly inspect the flange coupling for signs of wear, damage, or misalignment. Check for cracks, corrosion, or any deformations in the flange and bolt holes. Ensure that the coupling is properly aligned with the shafts.2. Lubrication: Lubricate the flange coupling as per the manufacturer’s recommendations. Proper lubrication helps reduce friction and wear between the mating surfaces of the flanges, bolts, and nuts. Use the right type of lubricant that is compatible with the coupling material.3. Bolt Torque Check: Check the bolt torque regularly to ensure that the flange coupling is securely fastened. Loose bolts can lead to misalignment and coupling failure. Follow the recommended torque values provided by the manufacturer.4. Alignment: Maintain proper shaft alignment to prevent excessive forces on the flange coupling. Misalignment can cause uneven load distribution and accelerated wear on the coupling components.5. Environmental Protection: If the flange coupling is exposed to harsh or corrosive environments, take necessary measures to protect it. Consider using protective coatings or seals to prevent corrosion and damage.6. Regular Servicing: Schedule regular servicing of the machinery or equipment, including the flange coupling. This allows for a thorough inspection and timely replacement of worn-out or damaged components.7. Replacement of Worn Parts: When signs of wear or damage are detected during inspections, replace the worn or damaged parts promptly. Delaying the replacement can lead to further damage and compromise the performance of the coupling.8. Follow Manufacturer’s Guidelines: Always follow the maintenance guidelines provided by the flange coupling manufacturer. They may have specific recommendations based on the design and material of the coupling. Proper maintenance and regular checks can extend the life of the flange coupling and contribute to the overall reliability and efficiency of the connected machinery. It is essential to create a maintenance schedule and adhere to it diligently to ensure the smooth operation of the flange coupling and the entire mechanical system.

editor by CX 2024-03-28

by

Leave a Reply